STRIP PREP

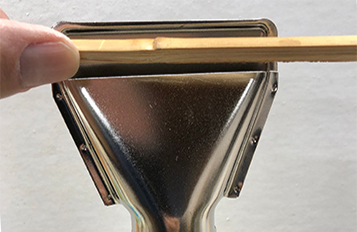

Twelve strips (six for the tip and six for the butt sections) can be tightly bundled up and put in an oven to be dried and strengthened. Fifteen minutes at 250°, fifteen minutes at 350°, finally, fifteen minutes at 250°. My oven is a four inch galvanized steel pipe inside an eight inch pipe. A heat gun blows down between the two pipes and up the four inch pipe where strips are suspended. Note, I have since wrapped the oven in fiberglass insulation to retain heat evenly top to bottom.